Corrosion resistant films prepared by HMDSO precursor system

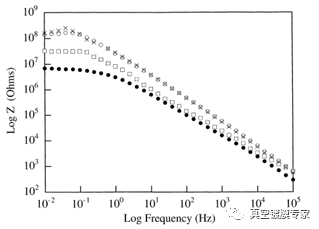

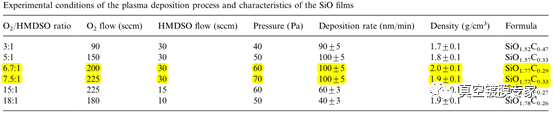

The introductionMetal products are indispensable in life, from ships and planes to nails and screws. The development of modern industry is based on metal as the skeleton, but metal is easy to corrode in the process of use. There are many kinds of anti-corrosion technology, vacuum coating is one of them. The use of PVD technology on the surface of a layer of corrosion resistant film layer, the plane or simple structure of the parts can play a very good protection; For complex structures, when all surfaces are required to be coated with protective film, CVD often has better coating ability and coverage due to its own principle. Using HMDSO as a precursor, a corrosion resistant film can be prepared on metal surface by PACVD technology.contentIn the process of preparing thin films in HMDSO/O2 atmosphere, HMDSO, as the silicon source, has a large number of H, OH, C groups in the process of ionization. C. Vautrin-ul et al. [1] used 2.45GHz microwave as an ion source to study the effect of HMDSO/O2 ratio on the composition and corrosion resistance of the generated films. FIG. 1 shows the ionization of gases measured by OES at different HMDSO/O2 ratios. We can see that with the increase of HMDSO ratio, the C group in plasma increases and the O group decreases. This change has an important effect on the composition of the membrane layer. When the proportion of HMDSO is low (about 20%), the membrane is close to silicon oxide; At high levels of HMDSO (about 80%), the membrane is more like a polymer.HMDSO as silicon sourceFIG. 1 Ionization of gases with different HMDSO/O2 ratios According to different proportions of HMDSO/O2 atmosphere conditions, C. Vautrin-ul [1] et al. analyzed its corrosion, as shown in FIG. 2. When the proportion of HMDSO is 80%, the impedance reaches the maximum value, indicating that its corrosion resistance reaches the maximum. As the proportion of HMDSO decreases, the impedance also decreases, and the corrosion resistance decreases.FIG. 2 EIS of the membrane under different HMDSO/O2 ratios (□) HMDSO/O2 100/0, (×) HMDSO/O2 80/20, (○) HMDSO/O2 50/50, (●) HMDSO/O2 20/80HMDSO/O2 ratios

18922924269

18922924269